Abstract:

Historically, the cranes of the ports are assumed to be static or cyclical but, due to higher speeds and loads, cranes are displaying dynamic behaviour. As a result, wear on the rail tracks is increasing and they are becoming insufficiently controlled. As one of the partners of Crane Dynamics (CRAMIC) global project, a mechanical model is developed to calculate the dynamic effects in the overall of the crane using the multibody dynamics approach: longitudinal, internal, rolling and track dynamics. The objective of this project is therefore to master, model and analyse the dynamic problems of “crane-track” systems.

Keywords: Cramic, Crane, Mechanics, Contact

Nowadays, cranes are displaying dynamic effects which are resulting in important damage to the crane, the track and its supporting foundations. This adversely affects the integrity of the crane rail system leading to reduced performance, system down time and costly repairs.

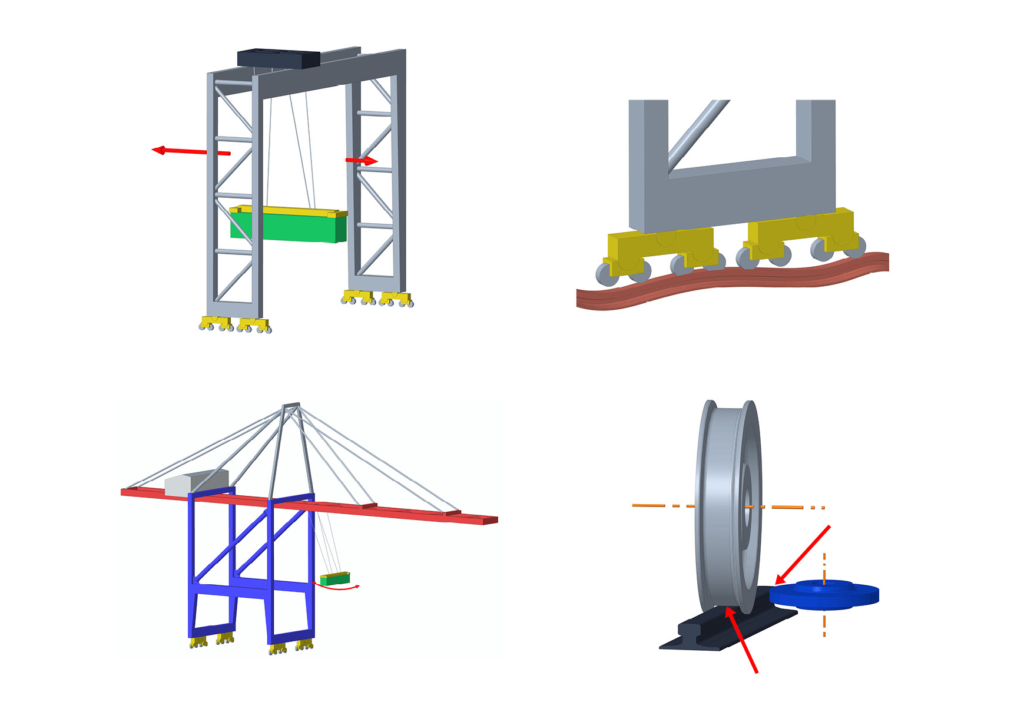

The origin of those dynamic effects can be explained by some phenomena, such as the ones listed below (Figure 2):

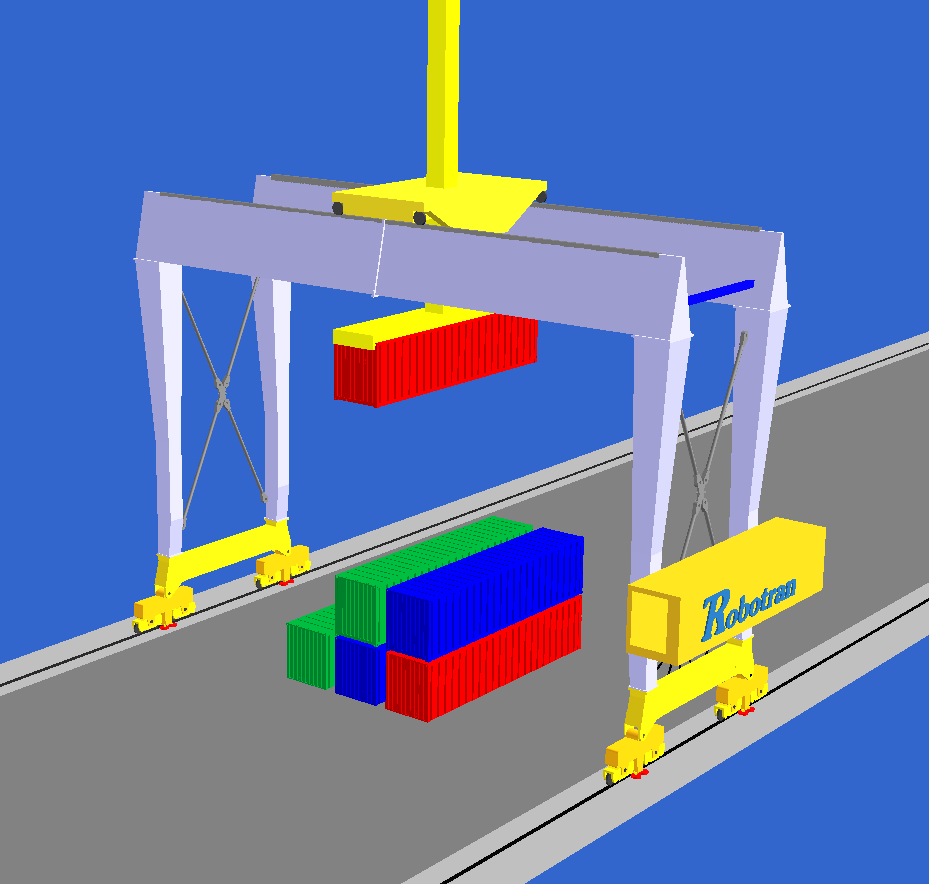

As one of the partners of CRAMIC global project, through granular and ROBOTRAN multibody analysis of the system crane-railway, the UCLouvain team focus on identifying and studying the present dynamic effects, participating in developing new track technologies and helping monitoring cranes to organize a future maintenance.

The project methodology is mainly based on 3 steps: modelling, simulation and validation. At present, since it is a project in progress, modelling and simulation are those which are being developed. After the finalization of the two first phases, the project will enter the validation phase. All of them are briefly explained below.

1. Modelling

In this first phase, different models are built and coupled: the cranes as a multi-articulated system, the roller/rail interface as a contact model and the ground infrastructure, as a bearing support and overall foundation. The steps of this phase are:

Since the model is defined, the next step is the simulation phase. However, this is an iterative process, so during the simulations the editing of the model is needed to adapt and to improve the model.

2. Simulations

The objective of this phase is to ensure a coupling between 3D multi-body models with high dynamics for the crane, a strongly non-linear contact model with respect to geometry (complex profiles of rails and rollers) and kinematics (contact sliding), over-constrained granular model (hyperstaticity of contact between grains) and extremely time-consuming.

To perform the simulations, the definition of different scenarios of the crane true to reality have to be made. These simulations require the definition of the following aspects:

3. Validation

The third phase consist of an iterative process with the two previous phases of the project to refine the model and proceed to its overall validation.

Internal partners:

External partners: